This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Drying with air is a process with the use of hot air, without chemicals, in which water evaporates from fresh vegetables and it ensures their long life span. It is called dehydration. Dried vegetables have a similar content of mineral salts and vitamins as fresh vegetables.

After dehydration the dry bulk is becoming concentrated and by the same the energy value, carbohydrates, fiber, mineral salts and even some vitamins are cumulated. Mild thermal processing in temperature and time, which is appropriate for a given product allows to keep the natural flavour of dried vegetables and sometimes it is even enhanced because of intense natural flavor and aroma.

The product drying technology applied by us is one of the oldest and the most popular method of preserving. Our modern machine park enables adjustment to diversified needs of clients.

The Drying Process

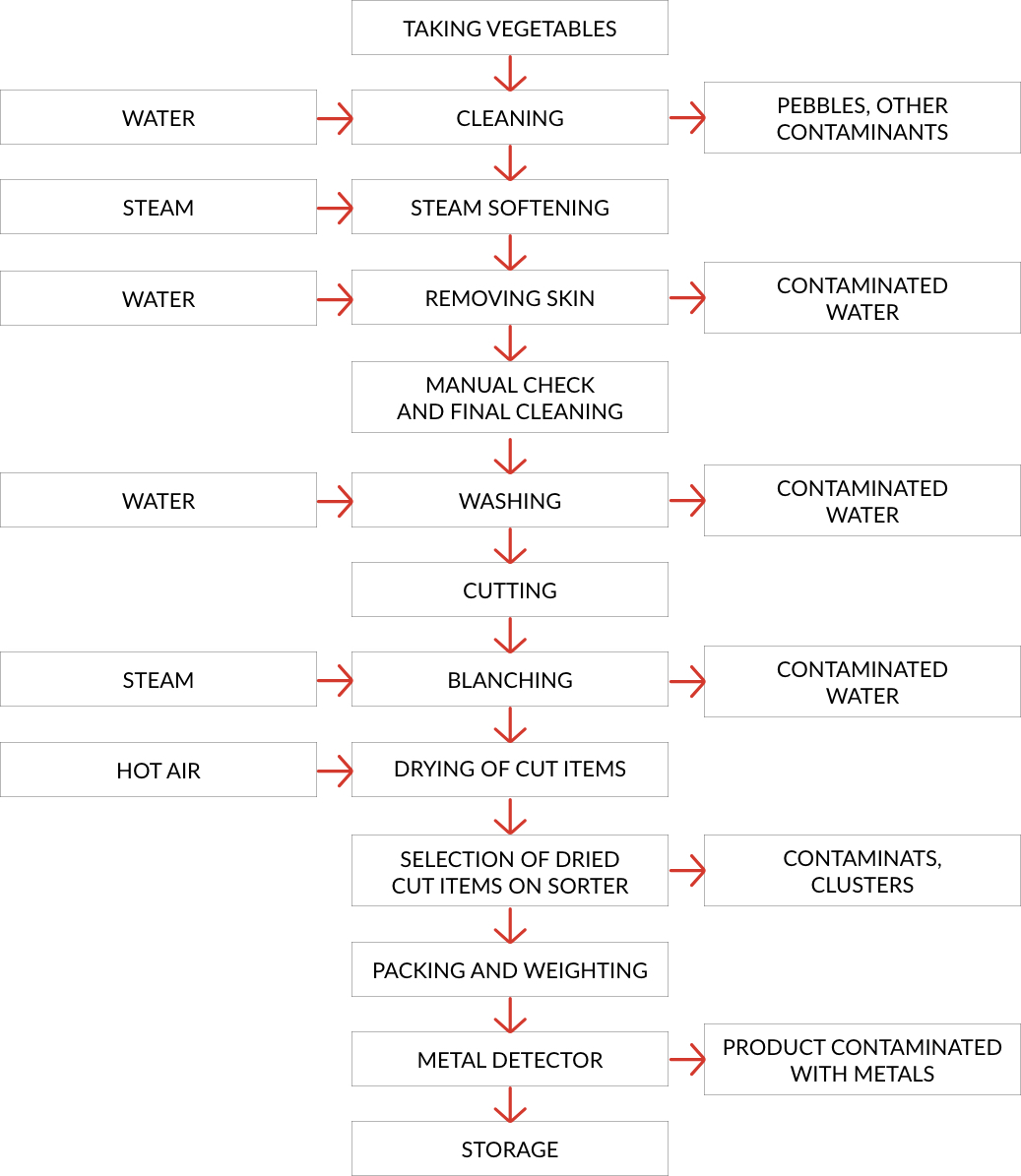

Deliveries of raw vegetables are accumulated in a storage yard of a raw material for daily throughput.

From the storage yard, vegetables are transported to a tippler bin, from where a system of conveyor belts supplies them to washer pebble removers, in which the remains of soil, pebbles and other contaminants are removed.

Afterwards, vegetables washed and deprived of pebbles are fed to a dispensing conveyor belt and, subsequently, to steam burners, in which, under pressure, steam softens the skin and the top layer of vegetables.

The steamed product reaches washer peelers. Here, the skin is grazed and washing takes place. Cleaned vegetables are transported onto an inspection belt for manual final cleaning.

Subsequently, the raw material is fed directly to successive washer pebble removers, to cutters and for thermal treatment in blanchers placed directly before drying units.

Blanched raw material is passed to drying chambers for a period of 5 to 11 hours, where it is subjected to the action of hot air, whose temperature varies from 40 to 95°C.

Dried cut items are directed by conveyor belts to a sorter. The separation of fine, proper and course fractions occurs here.

Sorted fractions are packed into paper sacks with a paper insert of microterm or polyethylene, weighed on electronic scales, checked with magnets and a metal detector.

After checking and marking, the sacks with semi-processed material are transported to the warehouse.